What is a Safety Relay? Simply Explained

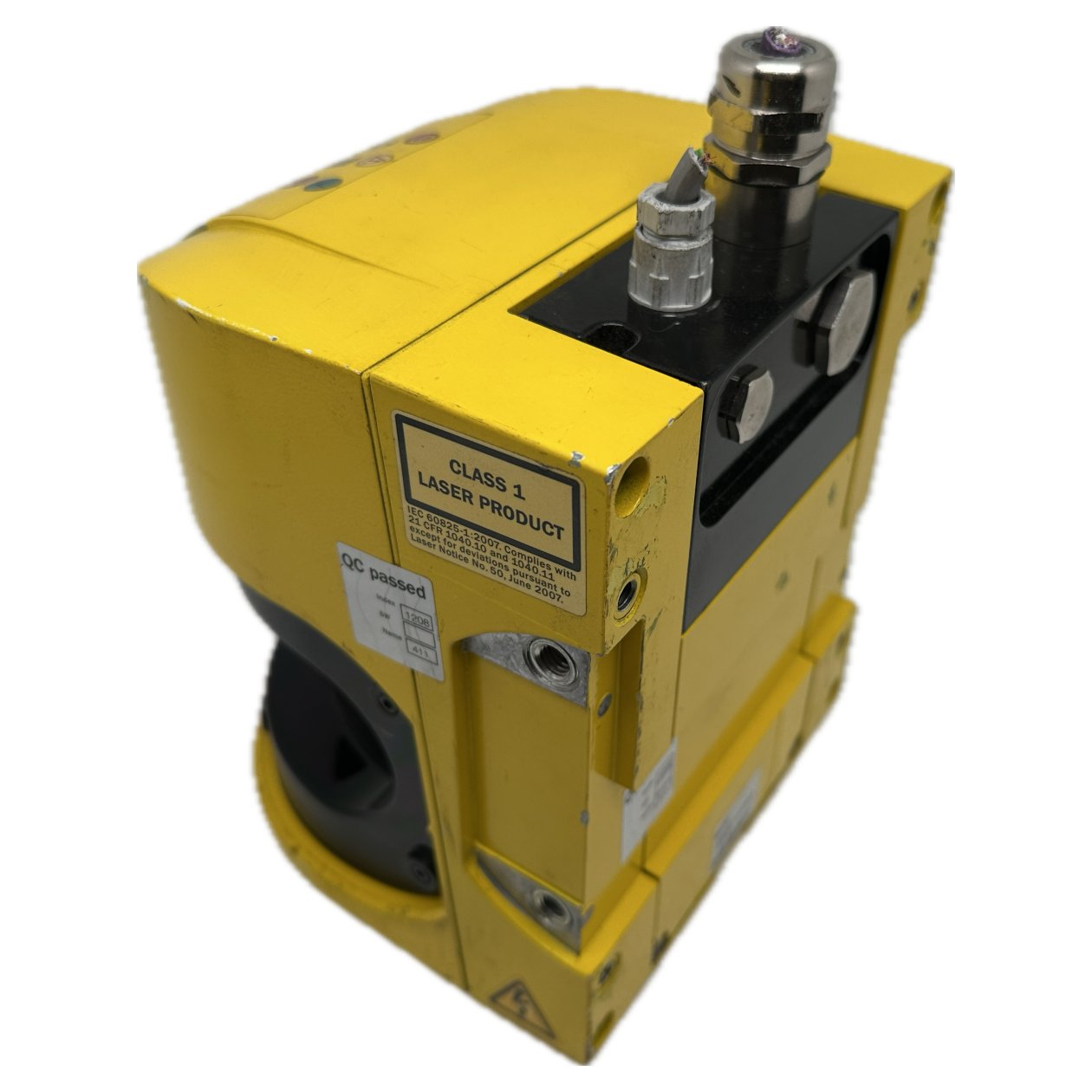

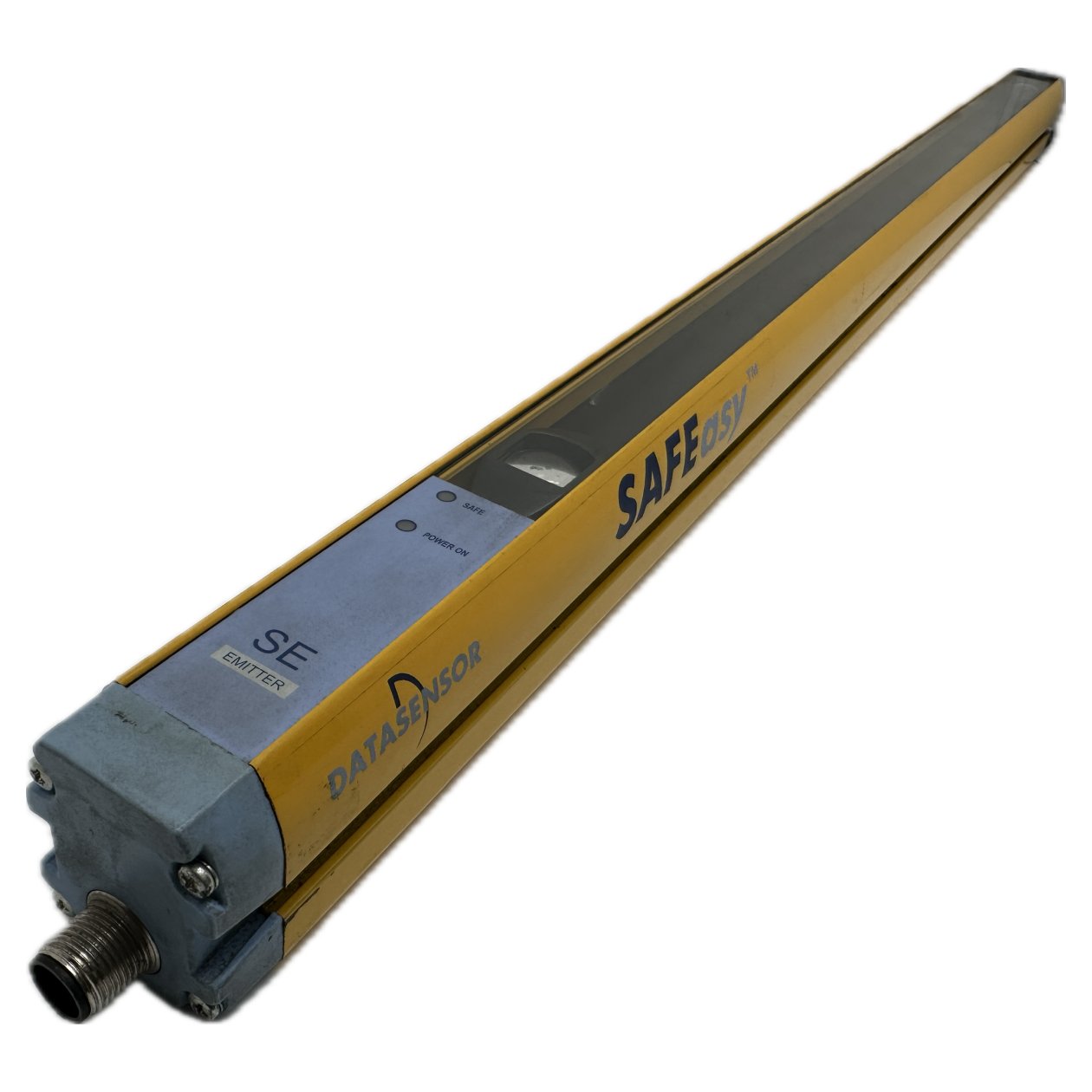

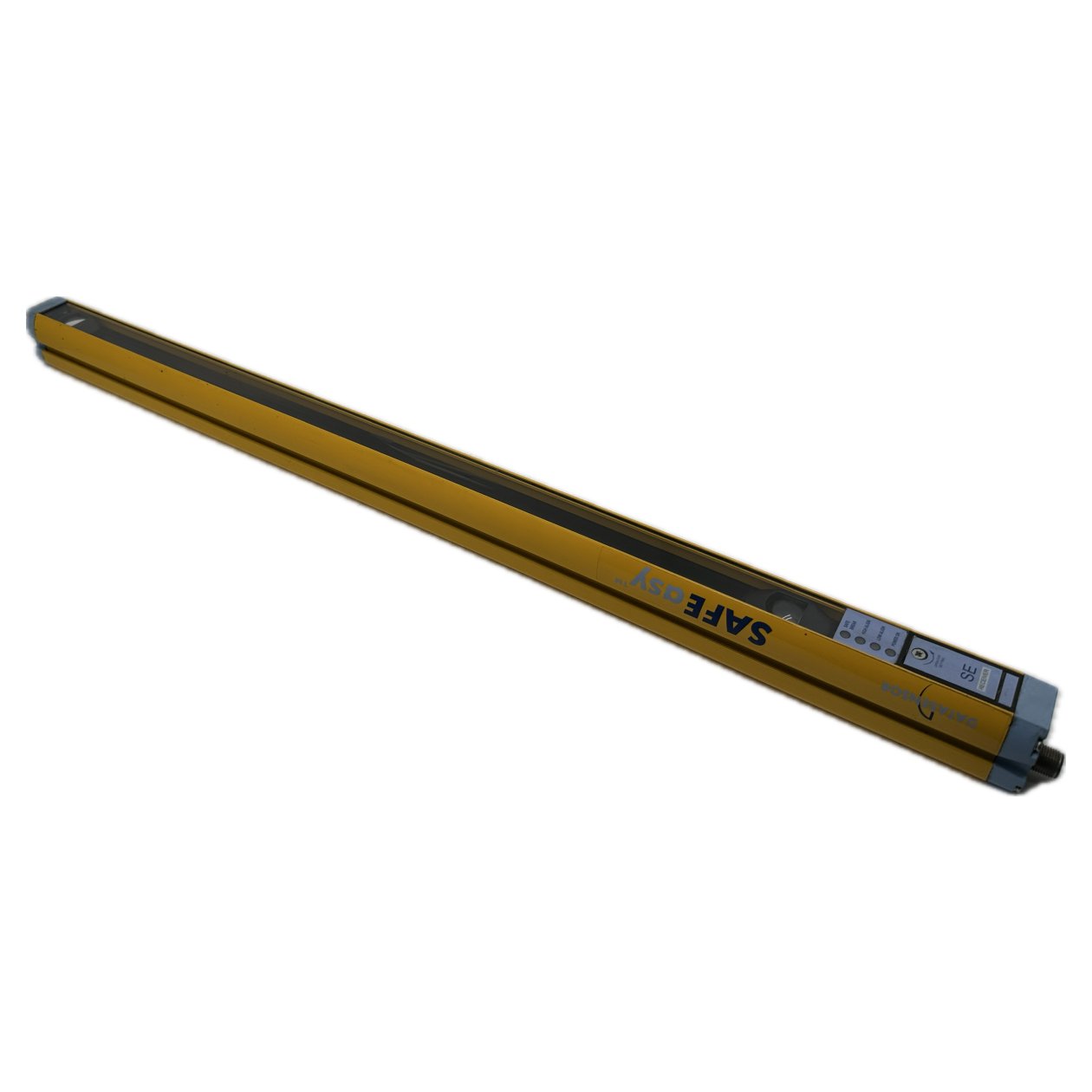

A safety relay is a specialized switching device that monitors safety-critical functions in machines and systems, and reliably shuts them down in hazardous situations. It is used to comply with safety standards when integrating emergency stop buttons, light curtains, or two-hand control devices.

🔧 How does a safety relay work?

Safety relays process input signals (e.g., from an emergency stop switch). When activated, the relay switches multiple contacts using safety-rated mechanisms (such as force-guided contacts) to cut power to hazardous components.

Typical features include redundancy (e.g., dual-channel inputs), self-monitoring, and failsafe shutdown in compliance with standards like ISO 13849 or EN 62061.

⚙️ Where are safety relays used?

- Industrial machinery: emergency stops, safety doors, light barriers

- Robot cells: protecting hazardous movement areas

- Conveyor systems: preventing unsafe access

- Presses & machine tools: enabling two-hand operation

- Building technology: e.g., elevator control systems

✅ Advantages of safety relays

- ✅ Standards-compliant safety: meets Machinery Directive & ISO 13849

- ✅ Easy integration: fits into existing control systems

- ✅ High availability: thanks to self-tests & diagnostics

- ✅ Cost-effective: compared to programmable safety controllers

⚠️ Disadvantages & limitations

- ❌ Limited flexibility: not programmable

- ❌ Only for basic safety tasks: not suited for complex logic

- ❌ Wiring effort: increases with more safety functions

📊 Comparison: Safety Relay vs. Safety PLC

| Feature | Safety Relay | Safety PLC |

|---|---|---|

| Programming | ❌ Not programmable | ✅ Fully programmable |

| Use case | Basic safety functions | Complex safety logic |

| Cost | 💰 Lower | 💰💰 Higher |

| Flexibility | ❌ Limited | ✅ High |

🧠 Conclusion: When is a safety relay the right choice?

A safety relay is a simple, cost-effective, and standards-compliant solution for basic safety tasks like emergency stop, door monitoring, or two-hand operation. For more complex systems with multiple safety zones or functions, a programmable safety PLC is often more suitable.

❓ Frequently Asked Questions (FAQ)

▶️ What’s the difference between a standard relay and a safety relay?

A safety relay includes additional monitoring features and force-guided contacts, making it suitable for safety-critical shutdowns.

▶️ When do I need a safety relay?

Whenever hazardous machine motion must be safely shut down in compliance with safety standards—e.g., using emergency stops, light curtains, or safety covers.

▶️ Are safety relays mandatory?

No, but a certified safety shutdown system is mandatory. Whether it's done via safety relay, safety PLC, or other devices depends on the risk assessment.