What is a Servo Drive? Simply Explained

A servo drive is an electronic control device that ensures servo motors do exactly what they are supposed to – with the highest precision and speed. Servo drives are the heart of modern automation technology – used in robots, CNC machines, packaging systems, or 3D printers.

🔧 How Does a Servo Drive Work?

A servo drive performs three main tasks:

- Signal Processing: It receives a target value signal (e.g., position, speed, or torque).

- Control: It compares this signal with the actual value from the motor (e.g., from an encoder).

- Output: It adjusts current or voltage to move the motor precisely.

This feedback loop is called a closed-loop control – enabling precise motion control.

⚙️ Typical Applications of Servo Drives

- Industrial robots: for precise arm movements

- Packaging machines: for accurate cycle timing

- CNC milling machines: for exact tool positioning

- Conveyor systems: for controlled speed

- Medical technology: e.g., in surgical robots

🛠️ Difference Between Servo Drives and Frequency Inverters

| Feature | Servo Drive | Frequency Inverter |

|---|---|---|

| Precision | Very high | Medium |

| Feedback (Sensor) | Yes (Closed-loop) | Optional (Open-loop) |

| Typical Motor | Servo Motor | Asynchronous Motor |

| Application | Robots, CNC | Fans, Pumps |

🧠 What Types of Servo Drives Exist?

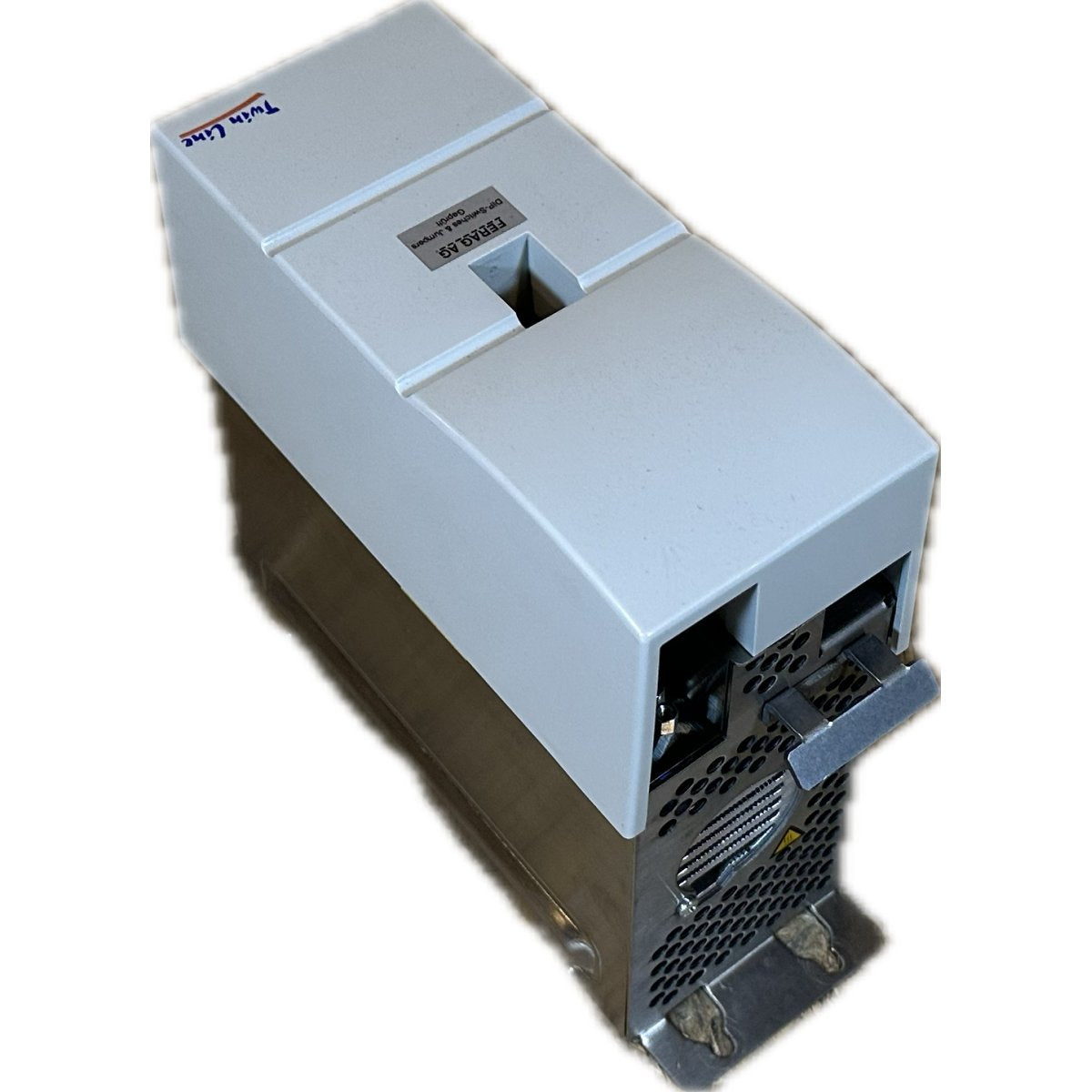

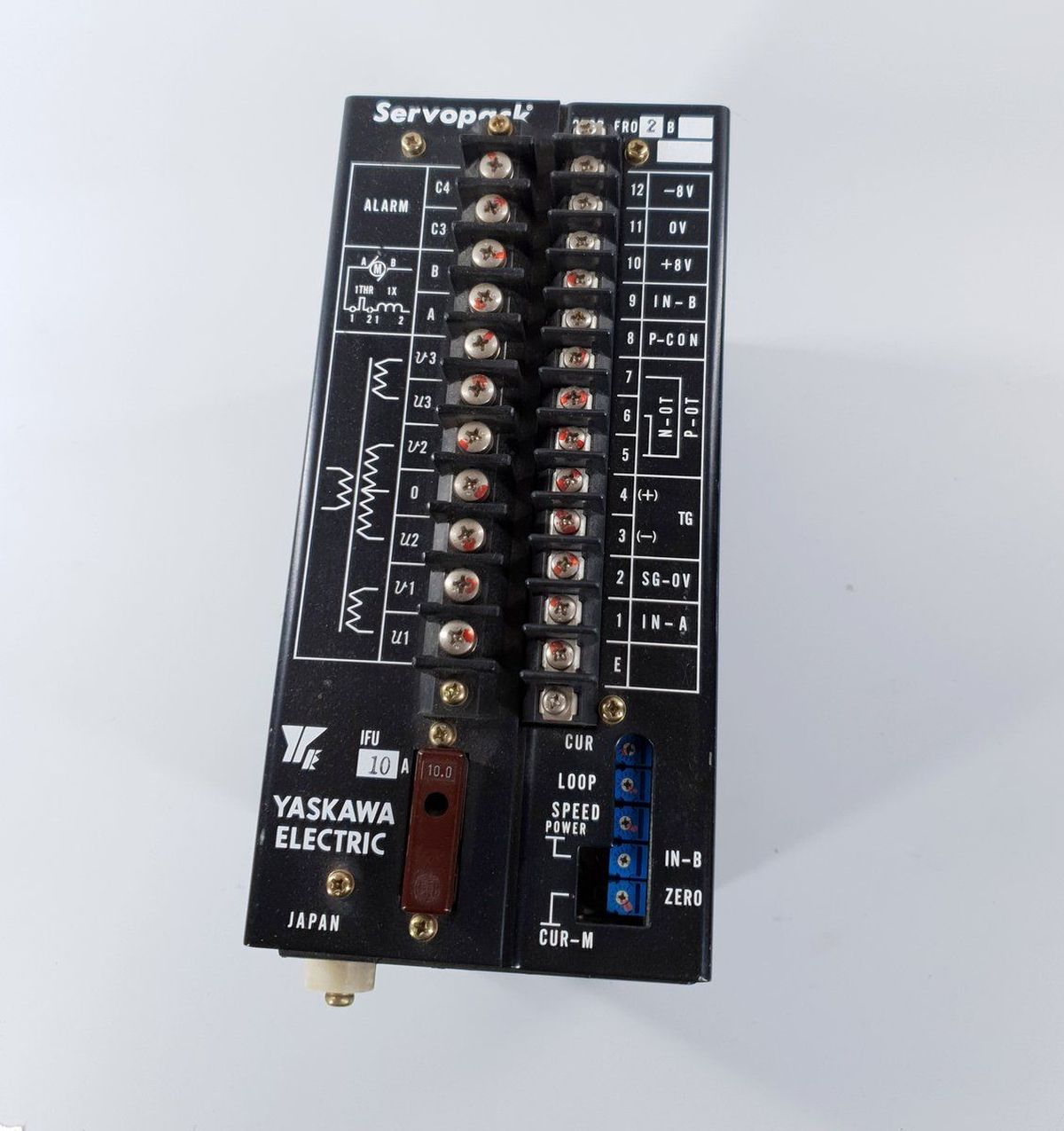

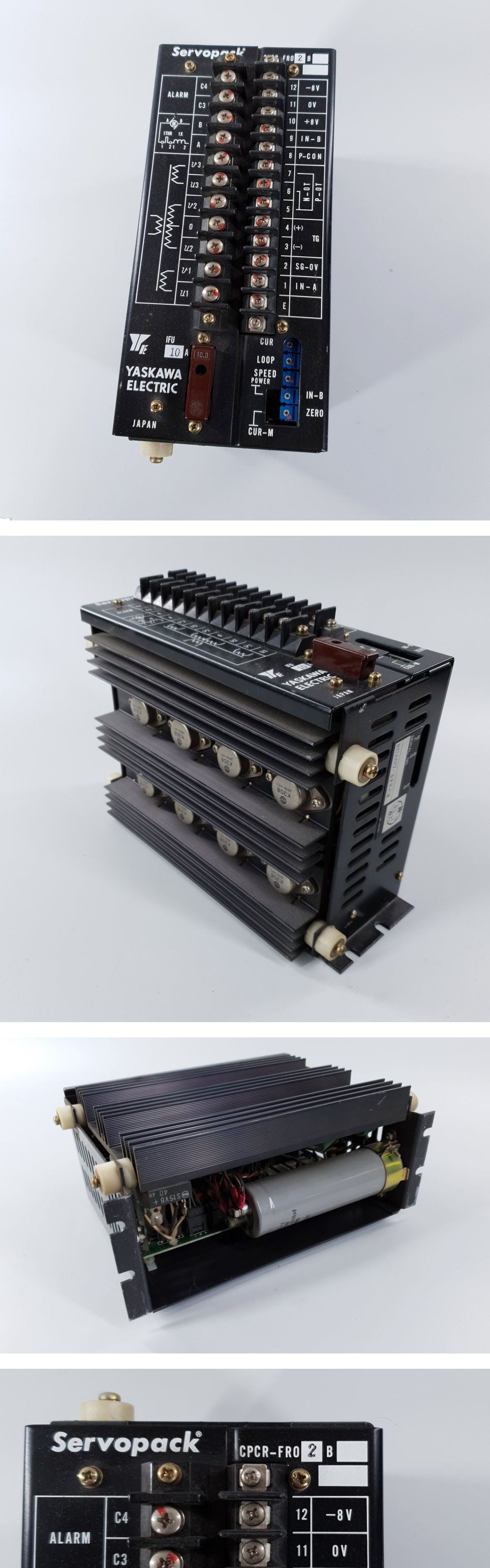

- Digital servo drives – industry standard

- Analog servo drives – rare

- Single-axis & multi-axis drives

- Compact all-in-one systems – for mobile or decentralized use

✅ Advantages of Servo Drives

- ✅ Highest positioning accuracy

- ✅ Energy-efficient through optimized motor control

- ✅ Integrated safety functions (e.g., STO)

- ✅ Connectivity via fieldbus (e.g., EtherCAT, CANopen)

🤔 Conclusion: Why Are Servo Drives So Important?

A servo drive is essential when motion precision and repeatability matter. It ensures perfect control in milliseconds.

💡 Tip: How to Choose the Right Servo Drive

- ✔️ Match the motor type

- ✔️ Consider the power class (voltage, current)

- ✔️ Ensure compatibility with your control system

- ✔️ Choose suitable interfaces (e.g., EtherCAT, Modbus)

❓ Frequently Asked Questions (FAQ)

▶️ What is the difference between a servo drive and a servo motor?

A servo motor is the actuator that performs mechanical movement. The servo drive processes control signals and regulates torque, speed, or position in real time. Both work together but fulfill different roles.

▶️ Which servo drives work with 230V mains power?

Many compact servo drives are designed to run on 230V AC mains power. They are especially suitable for small machines, automation tasks, or decentralized drives in industrial environments.

▶️ How does a servo drive work technically?

A servo drive receives target values from a controller, compares them with feedback values (e.g., from encoders), and continuously adjusts motor control via a control loop. This closed-loop regulation allows for precise positioning and motion.

▶️ When is a servo drive better than a frequency inverter?

If high precision, fast response, and accurate positioning are required – e.g., in robotics, CNC machines, or pick-and-place systems – a servo drive is the better choice. Frequency inverters are more suitable for basic speed control.