What Is an Actuator? Simply Explained

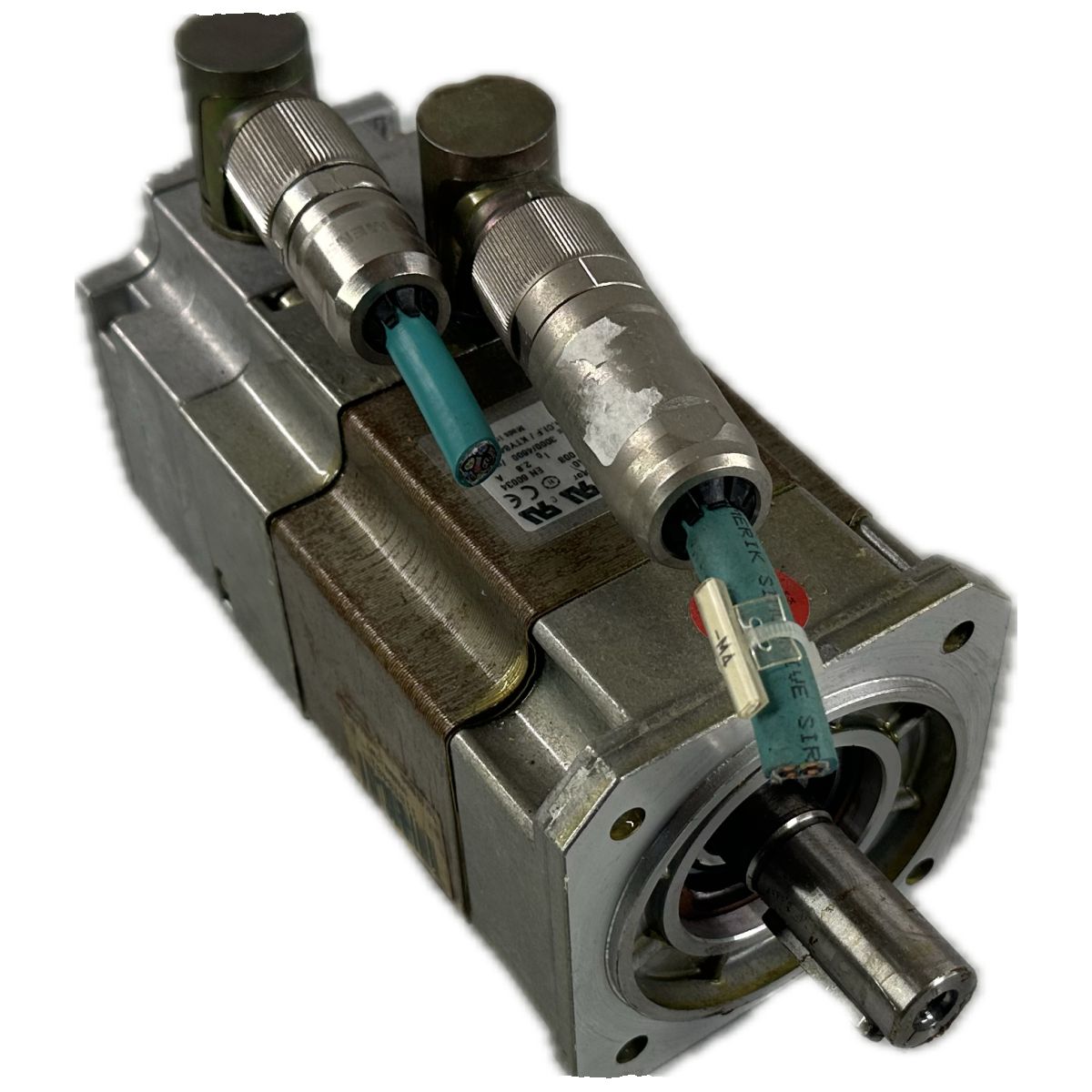

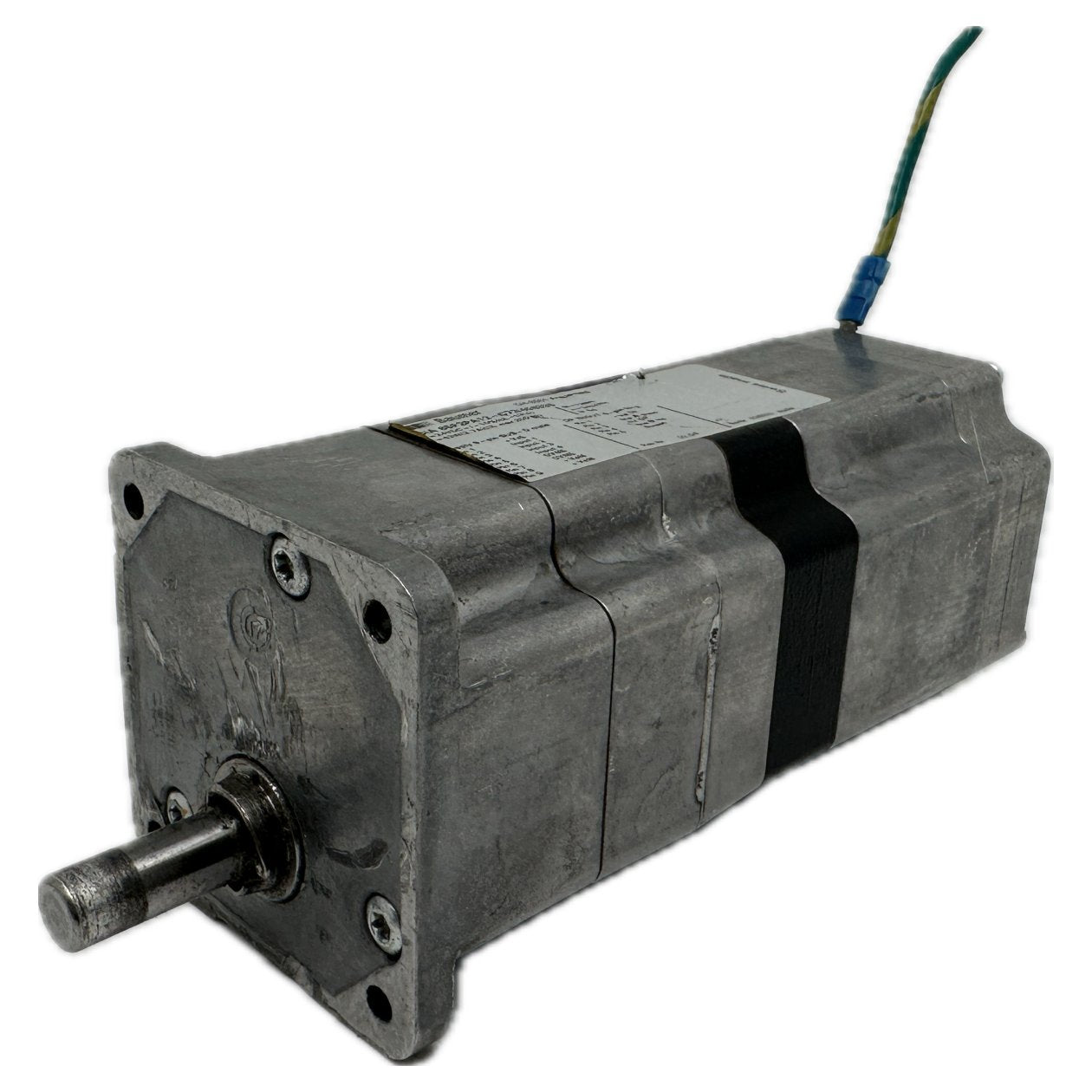

An actuator is a mechanical or electronic device that converts a control signal into a controlled movement – for example, to automatically open or close valves, dampers, slides, or throttles in machines or systems. Depending on the application, there are electric, pneumatic, or hydraulic types.

🔧 How Does an Actuator Work?

The basic process is always similar:

- A control unit sends an electrical or analog signal (e.g., 0–10 V, 4–20 mA, or digital commands).

- The actuator receives the signal and converts it into rotary or linear motion.

- A gearbox transmits the force to the moving part (e.g., the spindle of a valve).

- Optionally, sensors provide feedback on the current position.

Example: In a heating system, an actuator controls the flow through a radiator valve based on the room temperature.

⚙️ Where Are Actuators Used?

- Building automation – for heating, ventilation, and air conditioning systems (e.g., air damper control).

- Process industry – for controlling the flow of liquids or gases.

- Water & wastewater management – to operate pipeline valves.

- Mechanical engineering – in presses, packaging, or production systems.

- Power engineering – for turbines, steam lines, or boiler systems.

✅ Advantages of Actuators

- 🔹 Automated control – no manual intervention needed

- 🔹 Precise positioning – ideal for sensitive processes

- 🔹 High operational reliability – especially in critical systems

- 🔹 Versatile designs – scalable for various applications

⚠️ Disadvantages & Challenges

- ❌ Higher initial cost compared to manual solutions

- ❌ Requires regular maintenance for mechanically stressed components

- ❌ Sensitive to power failures (for electric versions)

📊 Comparison: Electric, Pneumatic or Hydraulic?

| Type | Features | Typical Application |

|---|---|---|

| Electric | Precise, quiet, easy to control | Buildings, HVAC, manufacturing |

| Pneumatic | Fast, reliable, requires compressed air | Industry, packaging |

| Hydraulic | Very high force, robust | Heavy industry, energy sector |

🧠 Conclusion: Why Are Actuators So Important?

Actuators are essential components in modern automated systems. They ensure precise, reliable, and energy-efficient motion – from heating systems to large-scale industrial plants.

❓ Frequently Asked Questions (FAQ)

▶️ What exactly does an actuator do?

An actuator converts an electrical or pneumatic signal into mechanical motion – for example, to open or close a valve.

▶️ What types of actuators are there?

The most common types are electric, pneumatic, and hydraulic actuators – depending on the required force, speed, or precision.

▶️ Where are actuators used?

In building automation, plant engineering, water management, or the process industry – wherever things need to be controlled automatically.

▶️ How long does an actuator last?

Depending on the design and usage, anywhere from several years to decades – provided it receives regular maintenance.