What Is a PLC? Simply Explained

A PLC (Programmable Logic Controller) is a digital control system used in automation technology. It replaces traditional wiring with a flexibly programmable control program. PLCs are used to control machines, systems, or processes automatically, safely, and efficiently.

🔧 How Does a PLC Work?

A PLC continuously processes inputs and generates outputs in a recurring cycle. The process includes:

- Reading input signals (e.g., from sensors or switches)

- Processing the programmed control logic

- Outputting control signals to actuators (e.g., motors, valves)

Typical: Cycle times are in the range of a few milliseconds – ideal for real-time control.

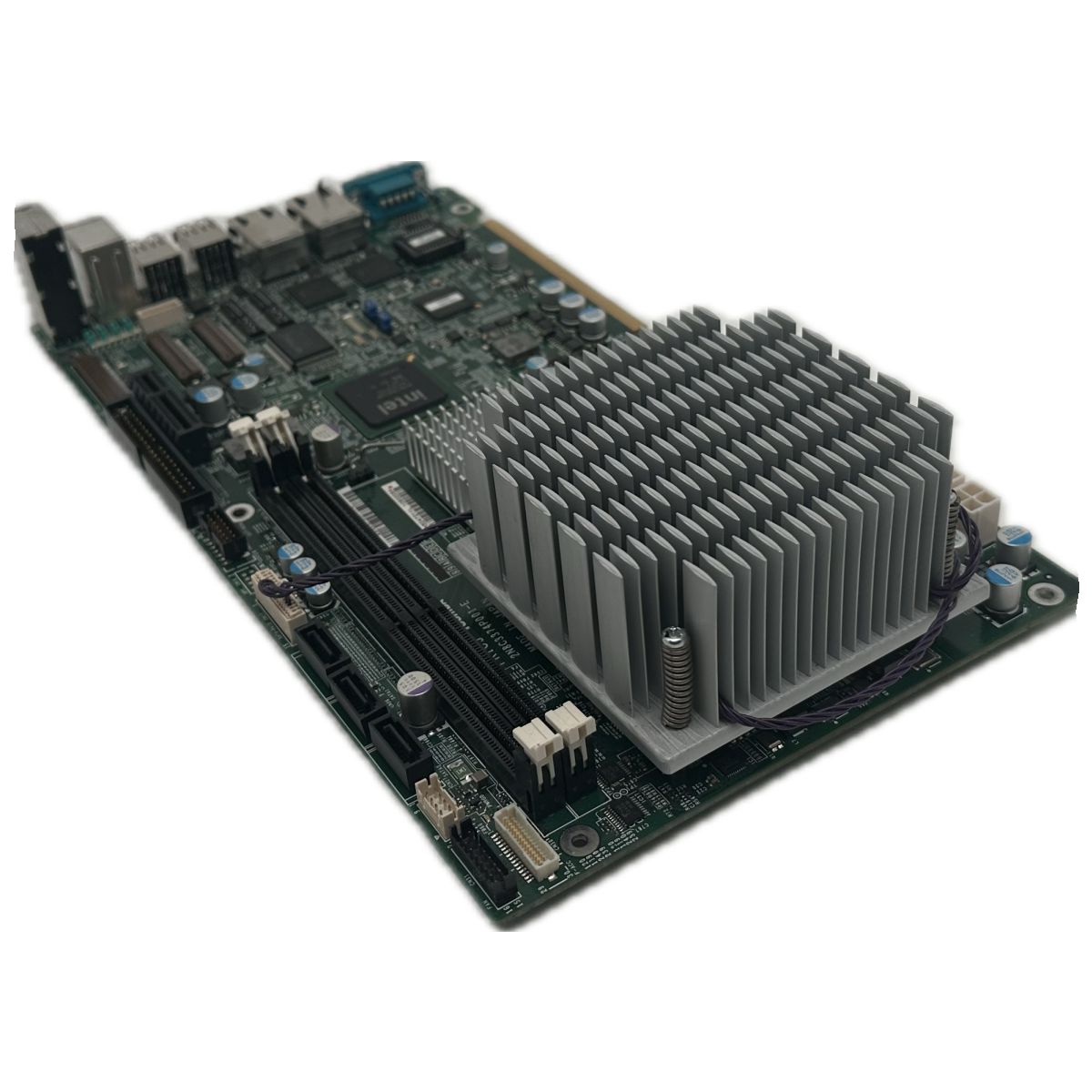

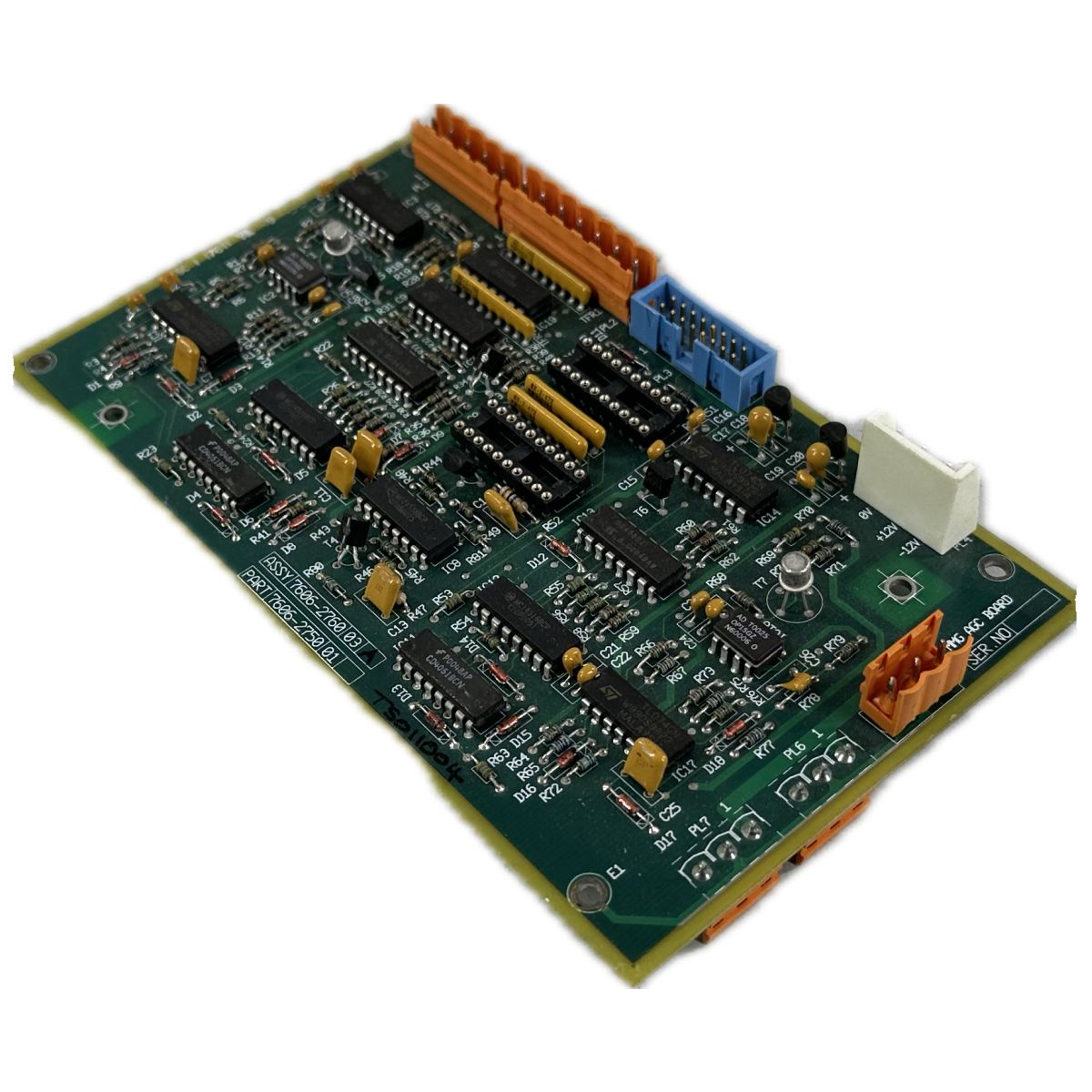

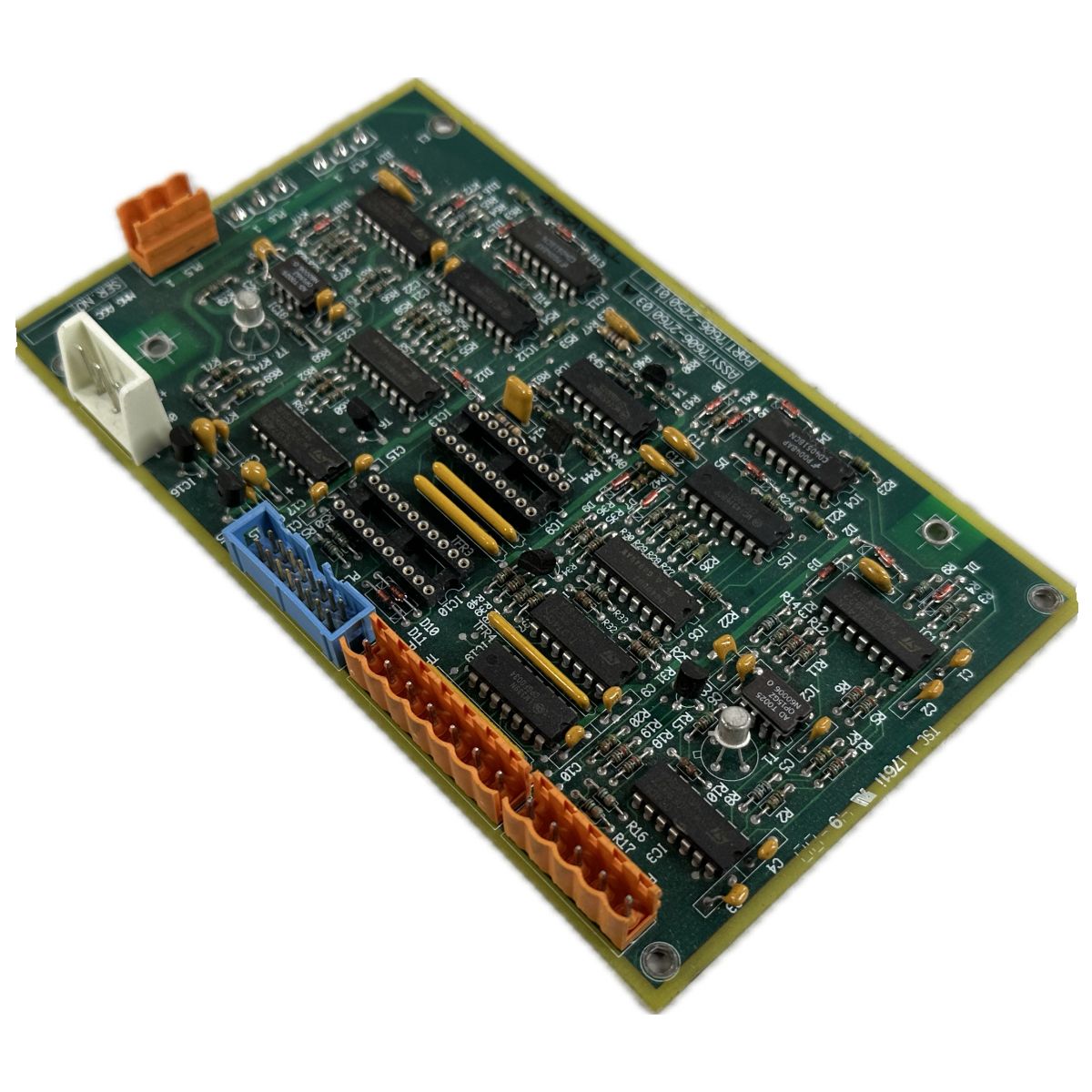

⚙️ What Components Make Up a PLC?

- CPU: processes the control program

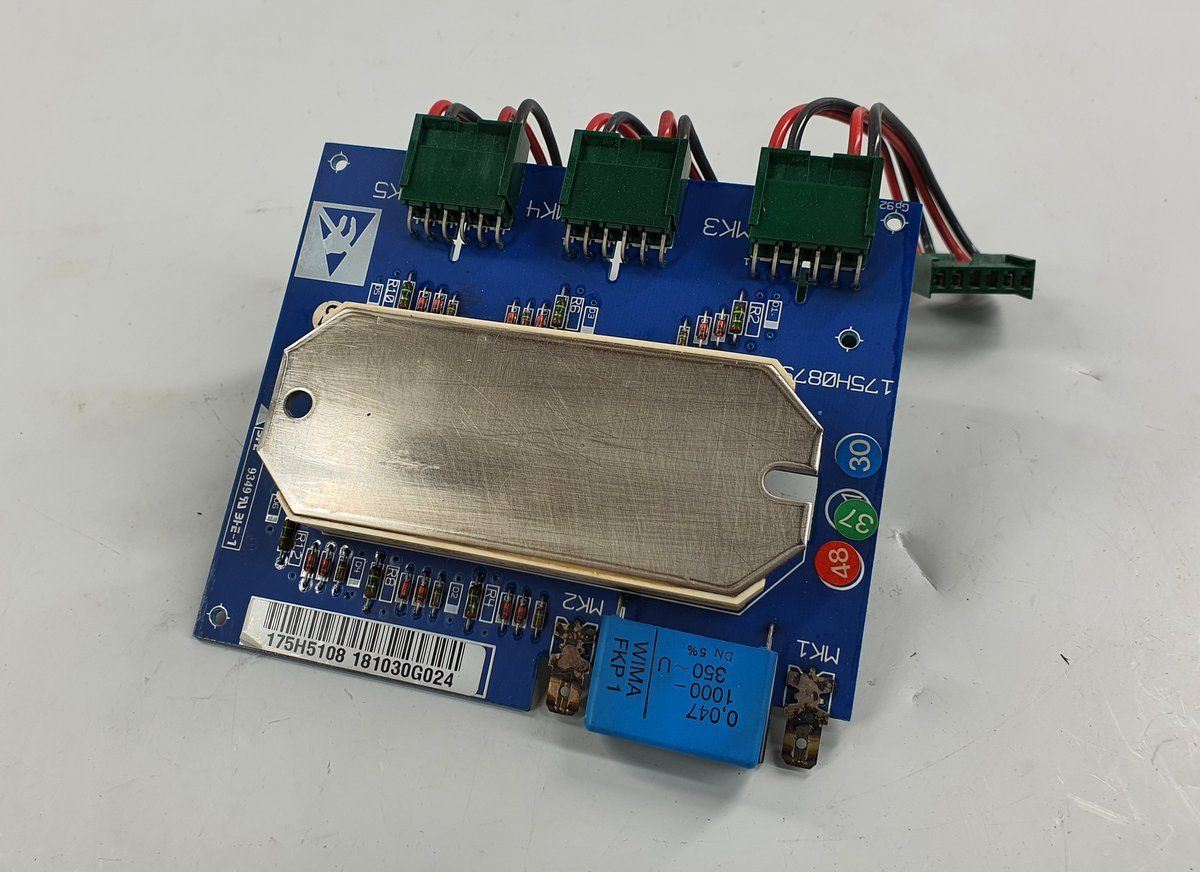

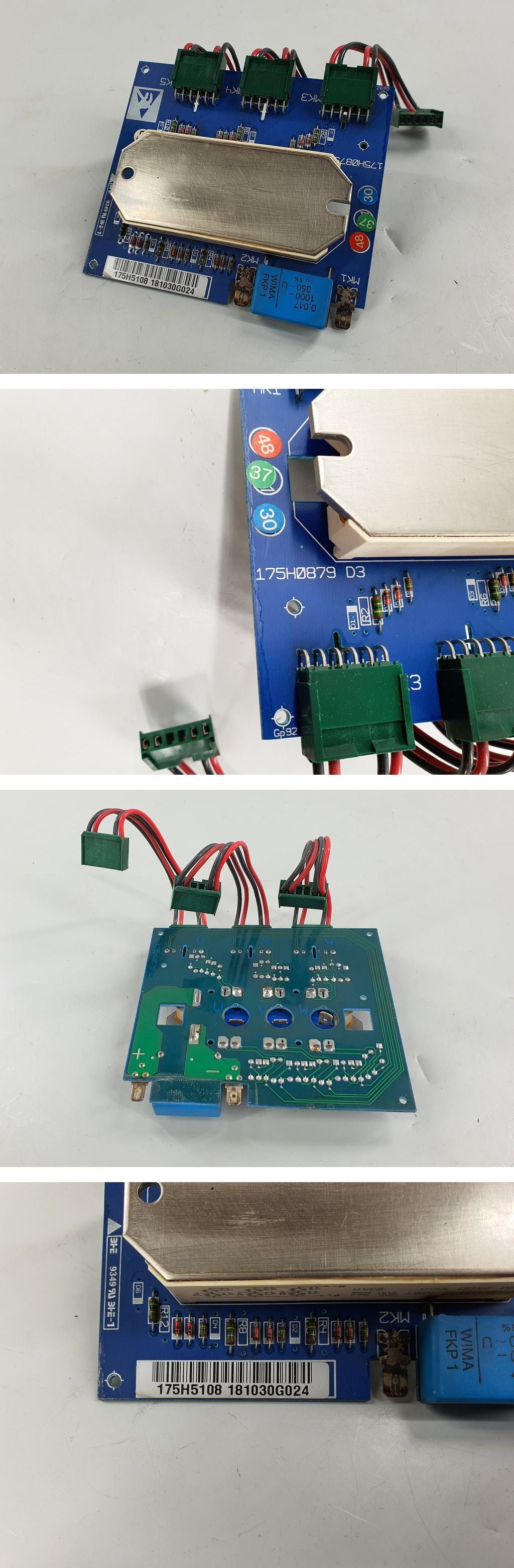

- Input modules: capture digital or analog signals

- Output modules: control machine components

- Programming interface: for uploading software

- Memory: for programs and process data

🧠 Advantages of a PLC

- ✅ Highly adaptable: changes made via software

- ✅ Reliable & robust: designed for continuous operation

- ✅ Modular scalability: I/O modules can be expanded as needed

- ✅ Network-capable: connects to HMI, SCADA, or cloud systems

⚠️ Disadvantages & Challenges

- ❌ Requires programming knowledge: e.g., in ST, FBD, or LAD

- ❌ Initial investment cost: higher than relay-based systems

- ❌ Manufacturer-dependent: often limited standardization in software

📊 Comparison: PLC vs. Classic Relay Control

| Criteria | PLC | Relay Logic |

|---|---|---|

| Flexibility | ✅ Very high | ❌ Low |

| Maintenance effort | ✅ Low | ❌ High (mechanical components) |

| Cost | 💰 Medium | 💰 Cheap for small applications |

| Application field | 🌐 Industry, manufacturing, process control | 🏠 Simple circuits |

📦 Well-Known PLC Manufacturers

- Siemens (SIMATIC S7)

- Beckhoff

- WAGO

- Schneider Electric

- Mitsubishi Electric

🧠 Conclusion: Why Is a PLC So Important?

PLC systems are the backbone of modern industrial automation. They offer maximum flexibility, reliability, and process safety. Whether in production lines, conveyor belts, or energy systems – PLCs enable automated workflows at the push of a button.

❓ Frequently Asked Questions (FAQ)

▶️ What exactly does a PLC do?

It automatically controls machines and systems by reading sensors and controlling actuators – based on a pre-programmed logic sequence.

▶️ What's the difference between a PLC and a PC-based controller?

A PLC is optimized for industrial use – more robust, fault-tolerant, and real-time capable. A PC is better suited for user interfaces or visualization.

▶️ Which programming languages are used for PLCs?

The standard is IEC 61131-3, including FBD (Function Block Diagram), LAD (Ladder Logic), ST (Structured Text), or SFC (Sequential Function Chart).

▶️ Where are PLCs used?

In industrial automation, mechanical engineering, elevator systems, power plants, logistics, or building automation.