What Is a Rectifier? Simply Explained

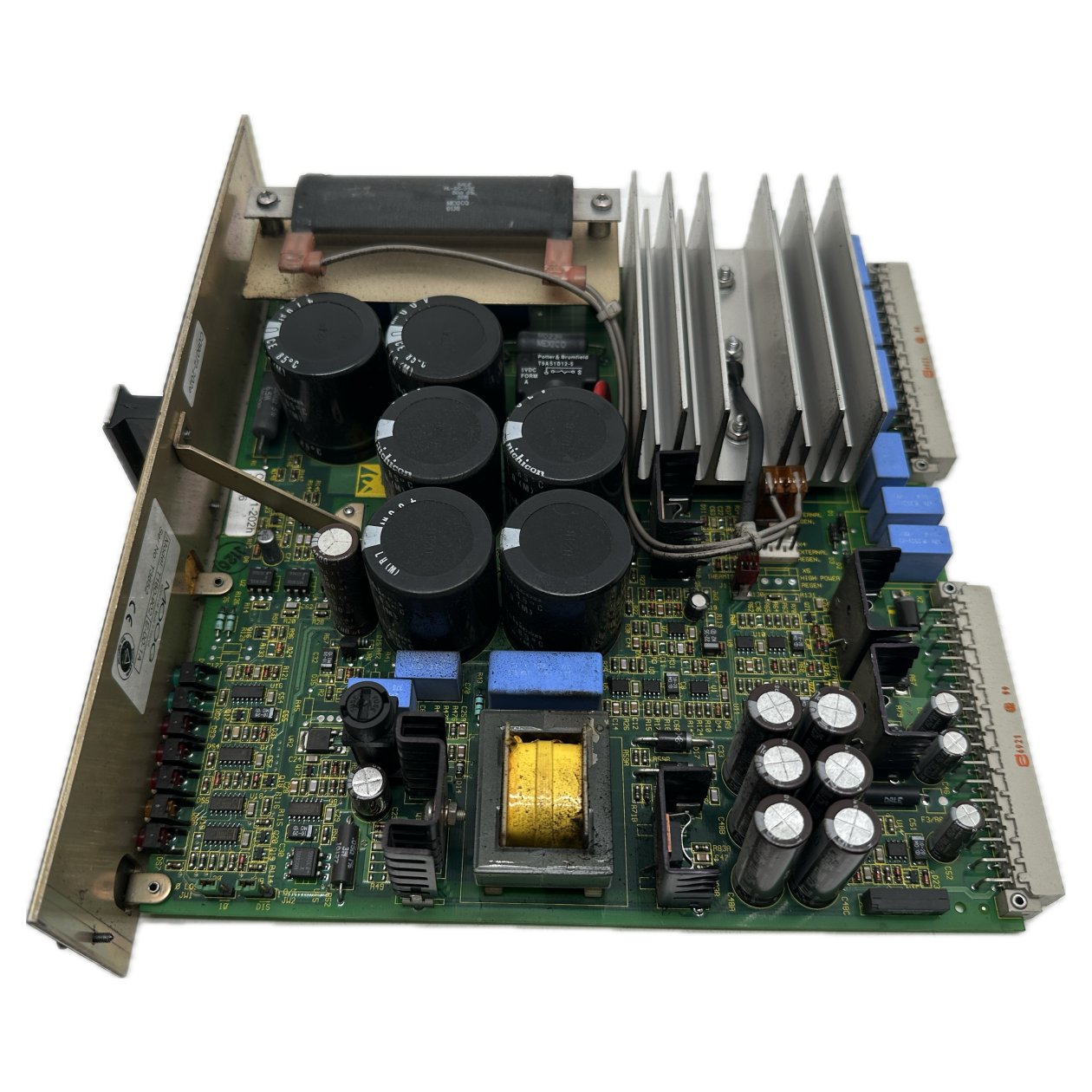

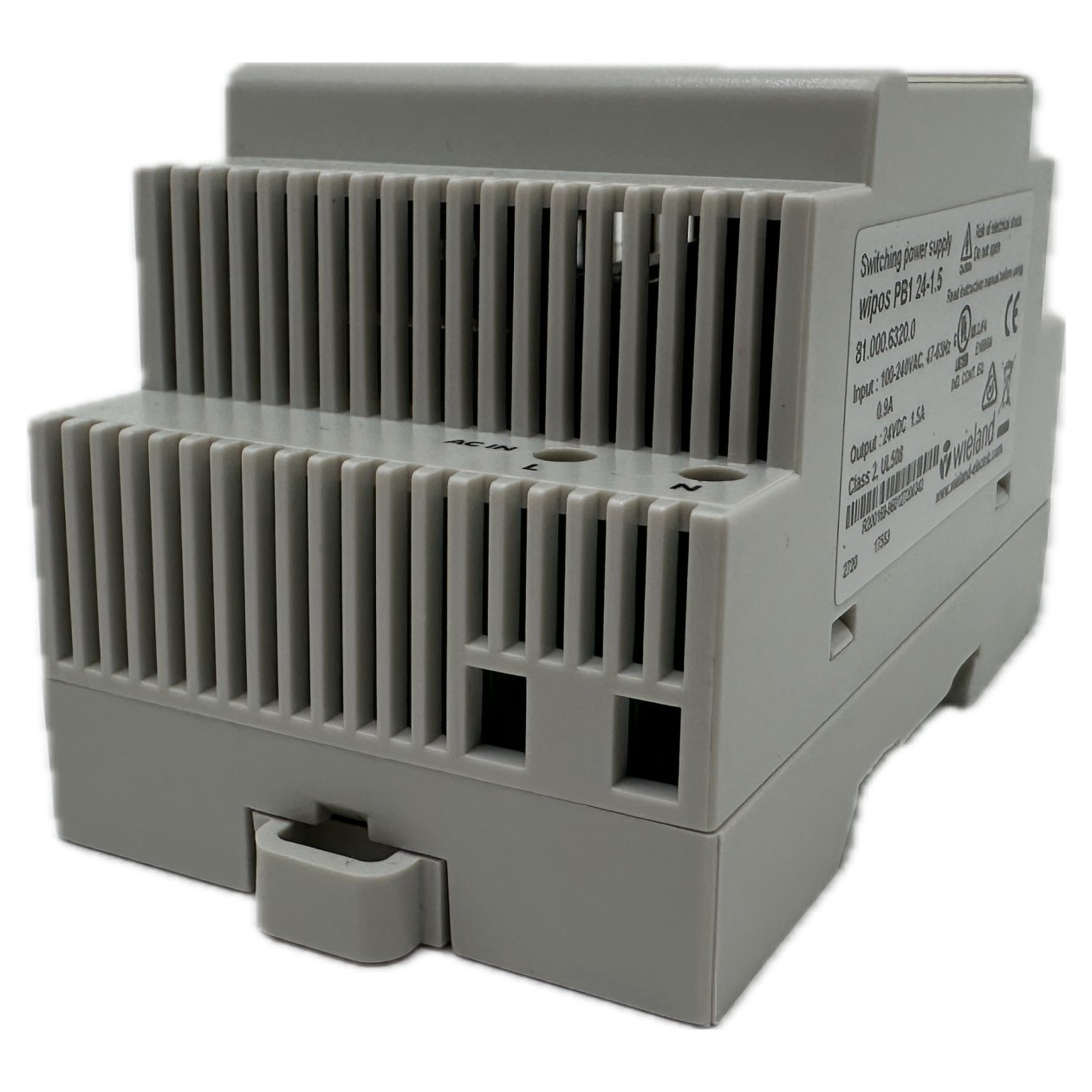

A rectifier is an electrical component that converts alternating current (AC) into direct current (DC). It is used in almost all devices that require a stable DC voltage – such as power supplies, chargers, or electronic control systems.

🔧 How Does a Rectifier Work?

Rectifiers use diodes that only allow current to flow in one direction. Several rectifier circuits exist:

- 🔹 Half-wave rectifier: uses only one half of the AC waveform

- 🔹 Bridge rectifier: uses four diodes to process both half-waves

- 🔹 Full-wave rectifier: a more efficient setup with two diodes and a center-tapped transformer

After rectification, the current is still pulsating. A smoothing capacitor is used to create a steady voltage output.

⚙️ Where Are Rectifiers Used?

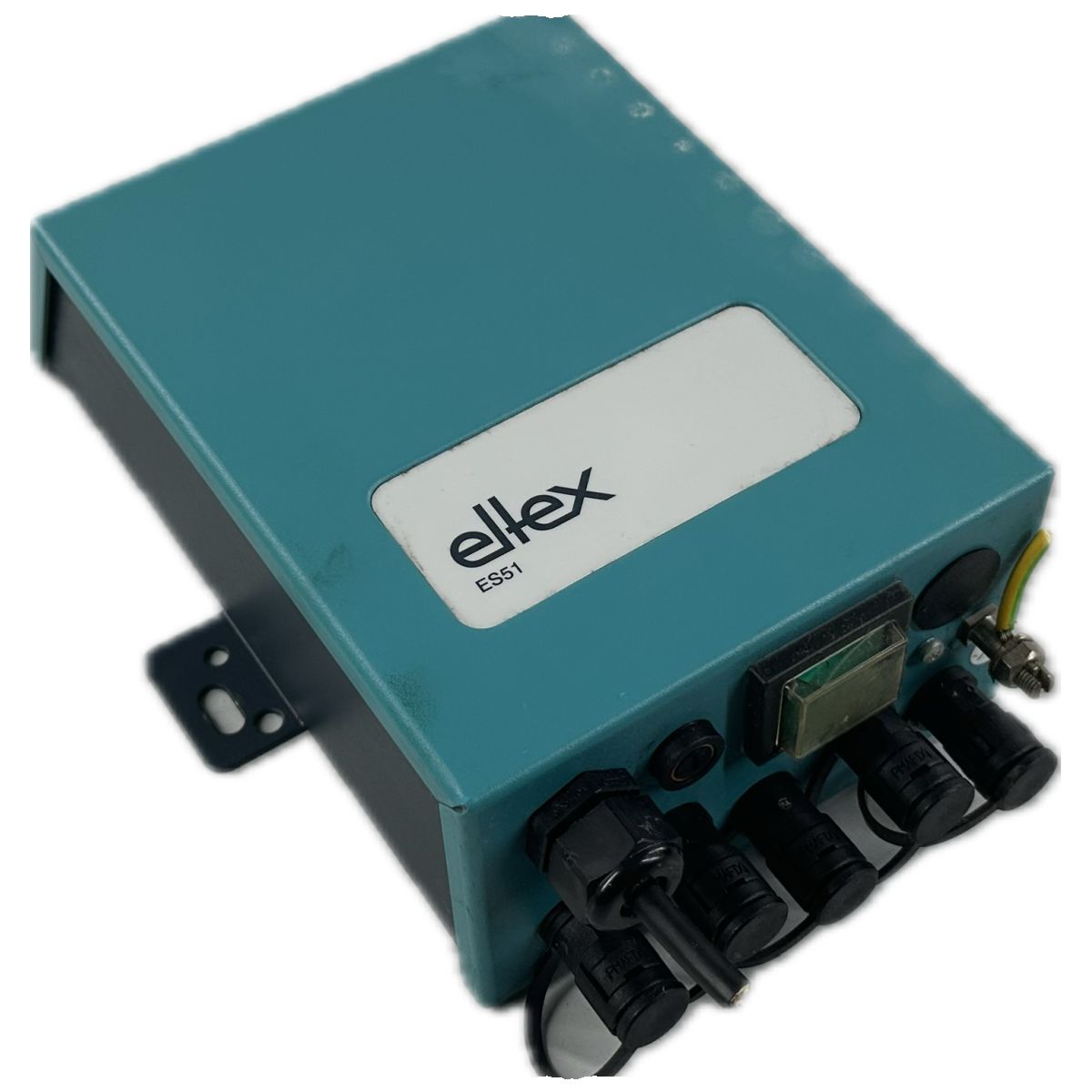

- Power supplies: converting 230 V AC to stable DC voltage for electronics

- Battery chargers: providing DC charging for batteries and accumulators

- Motor controllers: supplying DC motors from an AC source

- Solar & inverter systems: converting for grid feed-in or storage

- Welding equipment: providing stable current for industrial welding

🧠 Advantages of a Rectifier

- ✅ Simple & compact: diode circuits require minimal space

- ✅ Universally applicable: used in nearly every power conversion system

- ✅ Cost-effective: low material and manufacturing costs

⚠️ Disadvantages & Challenges

- ❌ Voltage drop: ~0.7 V loss per diode

- ❌ Ripple voltage: high ripple without filtering

- ❌ Heat generation: cooling required for high current loads

🧰 Types of Rectifiers Compared

| Type | Characteristics | Application Area |

|---|---|---|

| Half-wave rectifier | Simple circuit, only half the power used | Low voltage, basic power supplies |

| Bridge rectifier | Uses full waveform, 4 diodes | Standard in most power supplies |

| Full-wave rectifier (with transformer) | Two diodes + center tap transformer | Industrial applications |

🤖 Comparison: Rectifier vs. Voltage Regulator

| Feature | Rectifier | Voltage Regulator |

|---|---|---|

| Function | Converts AC to DC | Keeps DC voltage constant |

| Use phase | First step in power supply | After rectification |

| Components | Diodes, bridge circuit | ICs or transistor circuits |

🧠 Conclusion: When Do You Need a Rectifier?

Whenever electronic devices need to run on direct current from an alternating current source, a rectifier is essential. Whether it's a smartphone charger or an industrial control panel – rectifier technology is found everywhere.

❓ Frequently Asked Questions (FAQ)

▶️ What is a rectifier?

A rectifier converts alternating current (AC) into direct current (DC) – typically using diodes.

▶️ What types of rectifiers are there?

Half-wave, bridge, and full-wave rectifiers – depending on setup and use case.

▶️ Where are rectifiers used?

In power supplies, chargers, motor drives, or welding systems – anywhere DC is needed.

▶️ How is a rectifier different from a voltage regulator?

A rectifier converts AC to DC. A voltage regulator ensures a constant output voltage within the DC system.