What Are Sensors and Light Barriers? Simply Explained

Sensors are electronic components or systems that detect physical values such as temperature, light, distance, or motion and convert them into electrical signals. A special type of sensor is the light barrier – it detects the interruption of a light beam by an object.

🔧 How Do Sensors Work?

Sensors measure physical or chemical quantities and convert them into analog or digital signals. Depending on the type, there are:

- Temperature sensors (e.g. PT100, NTC)

- Motion sensors (e.g. PIR, radar)

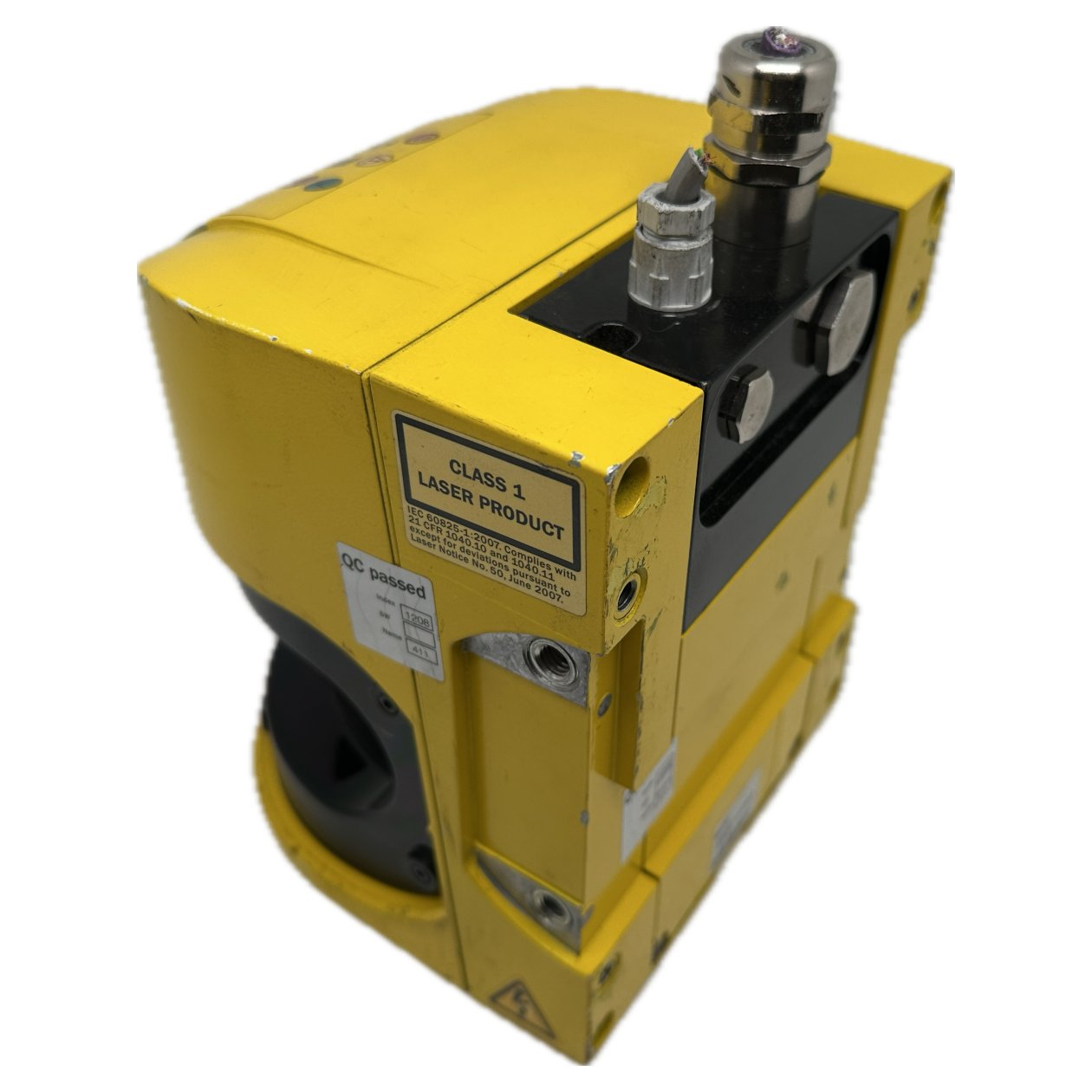

- Distance sensors (e.g. ultrasonic, laser)

- Pressure sensors, light sensors, and more

🔦 What Is a Light Barrier?

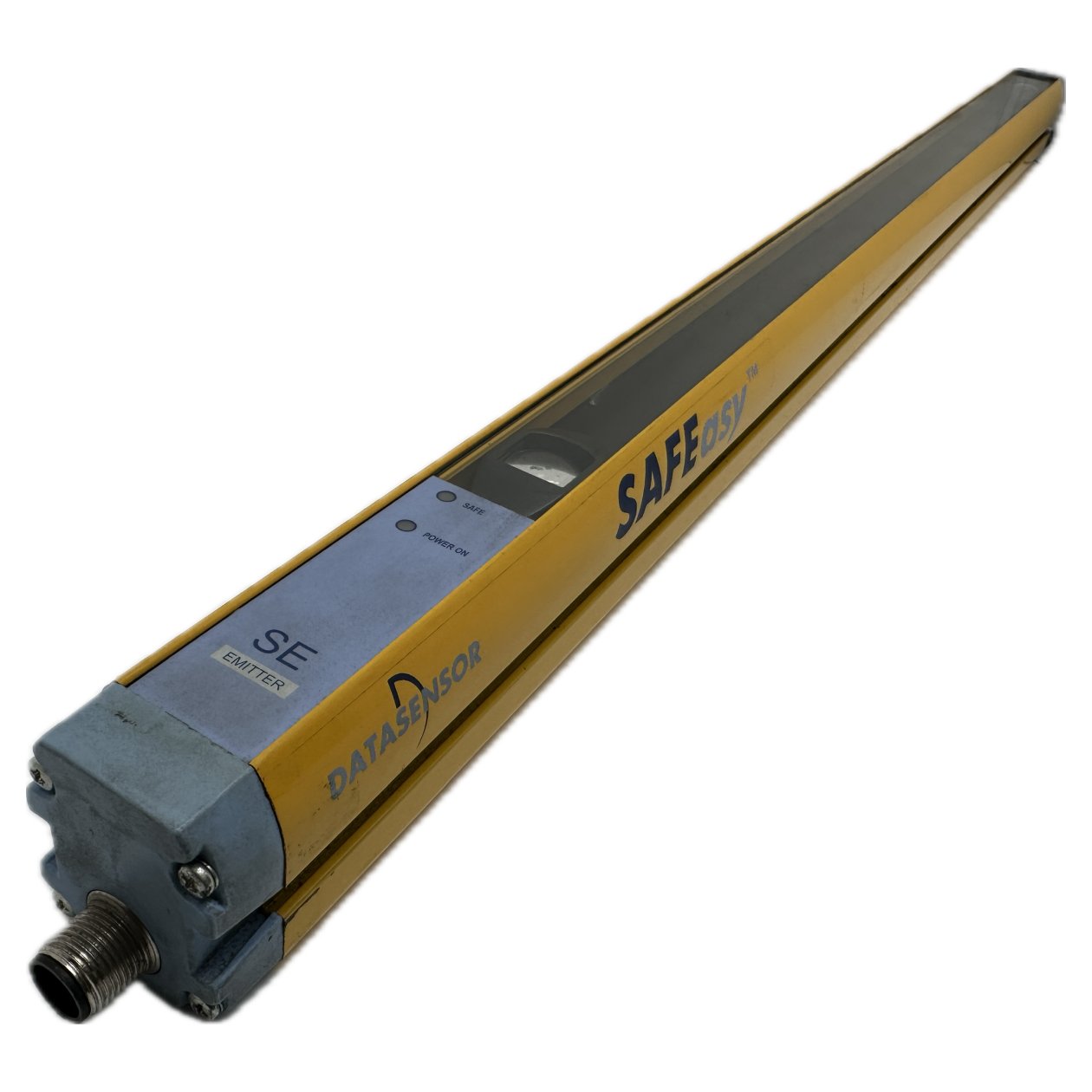

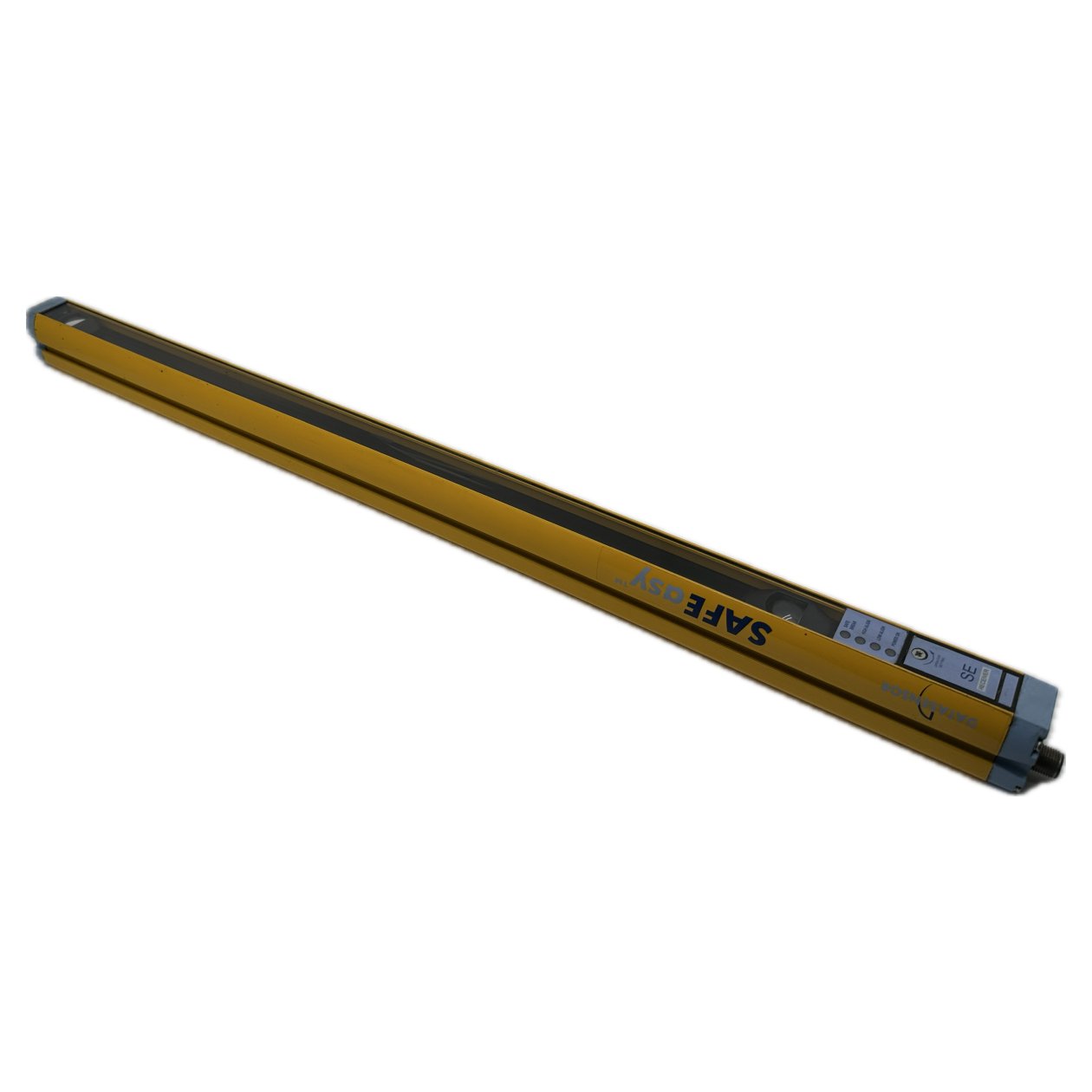

A light barrier is an optical sensor that detects the presence or absence of an object. It consists of:

- a light source (e.g. LED or laser)

- a receiver (photodiode)

If the light beam is interrupted, the system detects it as a "signal." There are three main types:

- Through-beam barrier – separate sender & receiver

- Retro-reflective barrier – uses a reflector

- Diffuse-reflective barrier – sender and receiver in one housing

📊 Sensor Types Comparison

| Type | Measured Quantity | Example |

|---|---|---|

| Temperature Sensor | Temperature (°C) | Heating control |

| Ultrasonic Sensor | Distance | Parking assistant |

| Light Barrier | Object detection | Conveyor belt, gate |

| Light Sensor (LDR) | Brightness | Street lighting |

✅ Advantages of Light Barriers

- Contactless object detection

- Very fast & reliable

- Suitable for industrial applications

- Detects even at high speeds

⚠️ Possible Disadvantages

- Susceptible to dirt or moisture

- Reflections may cause malfunctions

- Installation effort for through-beam systems

🧠 Conclusion: Sensors & Light Barriers in Everyday Use

Sensors – especially light barriers – are essential components of automation. They enable safe, fast, and contactless detection of states – from manufacturing to door control.

❓ Frequently Asked Questions (FAQ)

▶️ What is the difference between a sensor and a light barrier?

A light barrier is a specific type of sensor that works with light. Sensors in general measure many different quantities.

▶️ Where are light barriers used?

In conveyor systems, access control, production lines, rolling doors, or elevators.

▶️ Are light barriers safe?

Yes, many systems feature redundant safety mechanisms and are certified for industrial standards.